Markets

Digital Shelf-life for poultry products

Move from destructive lab and sensory testing to continuous freshness data in a digital platform.

Chicken is the most widely consumed protein, but can often be a source of off-odors and customer complaints.

Fresh chicken has a relatively short shelf-life (8-10 days in the UK, 15-20 days in the US) and often has a high pack-to-pack variation. Variation limits the shelf-life and results in spoilage and complaints from customers, but it is extremely hard to see with traditional testing, where you only get one data point per pack.

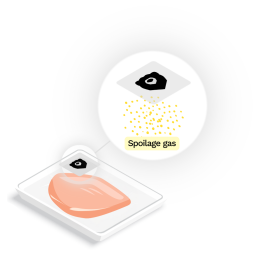

How it works

BlakBear sensors continuously measure spoilage gases and temperature inside the pack. BlakBear AI models convert this data into microbiological counts (like a TVC or APC, reported in cfu/g) and odor scores (on a 1-5 scale), so you can monitor shelf-life without opening the product. BlakBear shows the variation between packs, so you can determine the impact on shelf-life.

>90%

BlakBear signals correlated >90% with microbiology and sensory benchmarks on raw chicken in MAP, as validated by Campden BRI.

Applications

Periodic shelf-life verification and optimize MAP ratios

Supply-chain monitoring

Routine testing of batches and retained samples