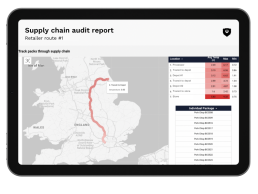

SUPPLY CHAIN

Track freshness and temperature at package level in real-time.

Cut product rejections and identify temperature impact on shelf-life across your network.

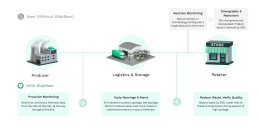

Identify cold-chain breaks and their effects on shelf-life

Improve quality

Identify the warmest points in your cold-chain, and their impact on shelf-life. Differences of 2 °C can cost 2 days of shelf-life

Cut rejections

Prevent rejections by identifying temperature problems before they cause spoilage

Continuous visibility

A single compete stream of temperature and spoilage data end-to-end, at package-level

Go from reactive to proactive

Applications

Periodic shelf-life verification and optimize MAP ratios

Routine testing of batches and retained samples