Pack variation

Unlocking the Key to Improving Quality and Extending Shelf-Life

BlakBear sensors are uniquely able to measure continuously through the entire shelf-life of a single pack of food. Read more on how understanding pack variation could be the first step to reducing it.

What is pack variation?

All packs of food, even two chicken breasts produced on the same line, on the same day from the same bird, will spoil differently. This is pack variation, but it is rarely spoken of because it is extremely hard to measure, even though it has major consequences for shelf-life. Food manufacturers need to choose sell-by dates that encompass all of the pack variation, to ensure safe and quality products for every customer.

So a high variation limits the shelf-life, even if most packs easily exceed the sell-by date.

Why is pack variation so hard to measure?

It has always been extremely hard to compare shelf-life across many products. This is because you traditionally get one data point per pack. You have to open the pack to test it (typically using microbiology and/or organoleptic methods), and then the pack is destroyed. You need many packs opened on multiple days, but then the averaging masks the pack variation.

One data point per pack makes it very different to quantify the difference between packs. Running a full shelf-life is also expensive (lots of packs, time, consumables, fridge space), so it is not always feasible to run many tests in parallel.

But now it is easy. With BlakBear you can run a full shelf-life test from a single pack. Just place a sensor inside and watch the data arrive in the software, with no need to open the pack.

Why is understanding pack variation valuable?

Understanding pack variation is the first step to reducing it, and therefore improving product reliability and potentially extending shelf-life. Understanding pack variation can identify improvements needed on the manufacturing line.

Pack Variation data can highlight issues with:

- Specific shifts

- Specific machines

- Specific seasons

- FSQA policies and procedures

Food manufacturers ideally want all products to be good to eat at the end of shelf-life. Reducing variation means a higher percentage of packs will make shelf-life. It may also create opportunities for extending shelf-life.

How does BlakBear show pack variation?

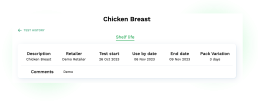

When you run a shelf-life test with BlakBear, you see a full shelf-life for every pack you test, so you can see how variation changes across the shelf-life and between packs.

You can also see a Pack Variation score, which you can easily compare across products, sites and time of the year.

What are the industry trends?

Some products have much higher variation than others. Fresh chicken has 24% higher variation than fresh pork. UK chicken for example, has a variation in shelf-life of 3.7 days, where as pork has 4.6 days.

The most extreme case we have seen was a fresh meat product with pack variation of 24 days. These packs of meat, produced at the same time and place, destined for the same supermarket shelf, had a shelf-life of ±10 days. Most of these packs were fine on the sell-by date, but 15% were not.

Schedule a demo

Let's shape the future of food quality and food waste.