1960's

Food testing is unchanged since the 60's.

Sensory and microbiology testing have been the same for decades, despite the sparse and imprecise data, high costs and reliance on manual labor.

What if every pack could test itself?

BlakBear sensors let food speak for itself: real-time freshness data, pack by pack. Instead of generalised batch testing and waiting days for lab results, every package would reveal its own freshness with a continuous digital profile of microbial growth and shelf life, so you can act sooner, waste less, and test smarter.

The first digital spoilage sensor from inside the pack.

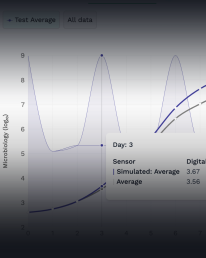

BlakBear has developed the industry’s first digital spoilage sensor small enough to be placed inside every pack, continuously monitoring freshness in real time. This tiny sensor works like a “digital nose” and thermometer combined: it continuously measures the actual indicators of spoilage inside the package, from the gases released as food ages (the same odors your nose picks up) to temperature and humidity levels.

Here's how BlakBear is transforming shelf-life testing.

Food quality testing used to mean one destructive test per pack, resulting in high costs and waste, all for a single data point. With BlakBear, we gather 1,000 times more data per test, providing us with unique insight into quality and minimising product waste.

Clive Stephens, Head of Research & Development, Cranswick